Product Category

Related Products

65t/h Flake Grate Stoker For Heating Furnace

Flake type chain grate is suitable for boilers with evaporation capacity less than 65 tons/hour. It is a single-layer layout of the overall quick-mounted grate, with stable and reliable operation performance, and is an ideal choice for small and medium-sized boiler plants and boilers.

Key Word:

Classification:

Flake Type Chain Grate

Email:

▌Product introduction

The grate surface of the scale-type grate is usually composed of 4~12 parallel chains (similar to the chain structure on a bicycle). Each chain uses a hoe bolt to string several chains composed of large rings, small rings, washers, liners and other components together. The grate plates are assembled on the chain through splints, which are folded back and forth, close to each other and in the shape of fish scales. When the grate plate moves to the tail and turns down into the empty stroke, it will turn over in turn depending on its own weight and hang upside down on the splint, which can automatically remove the ash and obtain cooling. Each adjacent chain is connected with the sleeve by a pull rod to keep the distance between the chains unchanged.

▌Applicable scope and requirements

(一)Scope of application

This grate is a mechanized boiler layer combustion equipment, which is applicable to boilers with evaporation capacity of 10~60t/h. It can burn bituminous coal, lignite and peat. It uses a coal hopper to automatically drop coal; It can also be equipped with wind power and coal feeder, or the grate can be inverted and equipped with mechanical wind power spreader to become a mechanized version of the suspended combustion chamber.

(二)Use requirements

The quality of coal used in this grate shall meet the following requirements:

(1) The maximum particle size of coal shall not exceed 40mm; The content of 0~3mm coal dust shall be less than 30%;

(2) The dry moisture content shall be less than 20%;

(3) The dry moisture content is not more than 30%, but not less than 10%;

(4) The ash deformation temperature shall be greater than 1250 ℃;

(5) The coking is not strong.

(6) If the above coal quality requirements conflict with the requirements of coal feeding equipment for coal quality, the highest one shall prevail.

The temperature of disposable air used in this grate shall not exceed 200 ℃ (for anthracite, it shall not exceed 160 ℃)

▌Structural features

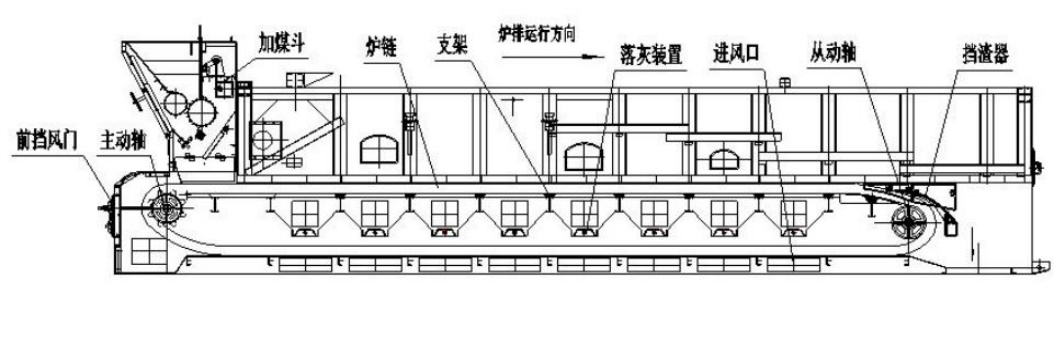

The whole grate is divided into seven parts: (1) driving shaft; (2) Driven shaft; (3) Support; (The support is of integral structure, with low ash supporting plate and friction strip); (4) Furnace chain; (5) Coal hopper; (6) Front damper; (7) Slag stopper. Air supply device of coal feeding equipment and grate gear box are not included in this grate.

▌Model parameters

| Boiler evaporation | Effective area of grate m2 | Effective width of grate mm | Outlet shaft length (to the grate centerline) mm | Diameter of output shaft end mm | Number of air chambers |

| 2 t/h | 3.04 | 1040 | 802 | Φ60 | 3 |

| 4 t/h | 5.97 | 1332 | 1050 | Φ80 | 5 |

| 6 t/h | 7.36 | 1560 | 1089 | Φ80 | 5 |

| 8 t/h | 8.26 | 2000 | 1425 | Φ80 | 4 |

| 10 t/h | 10.5 | 2000 | 1470 | Φ95 | 6 |

| 15 t/h | 15.57 | 2664 | 1835 | Φ100 | 5 |

| 20 t/h | 22.08 | 3434 | 2079 | Φ120 | 6 |

| 30 t/h | 27.39 | 3804 | 2400 | Φ130 | 6 |

| 40 t/h | 35.44 | 4544 | 2771 | Φ130 | 7 |

▌Structure and characteristics

(1) The grate working face, that is, the part of the grate surface, has many grate bars continuously and obliquely stacked in scaly shape, and the ventilation section is 8% - 10%.

(2) The structural feature of the furnace chain is that there are multiple chains, and the chain is fixed on the furnace chain by a group of five splint columns. The furnace chain is fixed by a long shaft and a liner in series, and rollers are strung between the furnace chains. The roller engages with the tooth on the main wheel, and the chain wheel of the transmission furnace rotates. The operation of the grate is pushed by the driving wheel, and the driven wheel is sliding.

(3) Sectional air supply is adopted inside the grate. It is divided into several large-capacity air chambers longitudinally along the grate, and each air chamber is separately connected with the air supply pipe. The wind entering the air chamber reduces its speed due to diffusion and can evenly fill the air chamber. There is a butterfly door on the air supply pipe to regulate the air pressure in the air chamber.

(4) Push-pull and pull rod ash drop doors are used for the ash discharge device of the air chamber. When the handle of the ash drop door is turned or pushed, the ash will fall on the lower furnace chain. The furnace chain moves on the lower bottom plate to push the ash to the front of the grate and fall into the ash hopper or slag chute. The ash can also be removed manually. The push handle is placed outside the air supply pipe through the air supply pipe, and its layout is consistent with that of the air supply pipe, that is, when the air is supplied from one side, the ash is discharged from one side; When air is supplied from both sides, ash is discharged from both sides; Air supply from one side, and ash discharge from both sides.

(5) The seal between the two sides of the furnace chain and the support adopts labyrinth or contact structure, and the coal blocks are placed to leak into the two sides of the grate.

(6) The slag retaining device adopts eagle iron slag retaining device. The slag stopper, namely eagle iron, is placed behind the driven shaft, its head is pressed on the furnace chain by its own weight, and its lower part is installed on the shelf, which is welded with the grate support.

(7) In order to meet the needs of inspection, maintenance and ventilation at ordinary times, an inspection door is set on the slope above the front damper. If natural ventilation is required, the damper and the ash drop door of the air chamber can be opened.

(8) The coal hopper is installed on the wall panels on both sides of the support. There is a coal gate in the coal hopper. The thickness of the coal seam is adjusted by the lifting of the gate.

▌Advantage

1. The coal seam is in contact with the whole grate surface, but the chain is not directly heated, and the operation is safe and reliable;

2. The grate clearance is very small and there is little coal leakage; The grate plate is thin and the cooling condition is good;

3. It can be replaced without stopping the boiler;

4. Due to the flexible structure of the chain, when the tooth shape of the sprocket on the driving shaft is slightly uneven, the tightness can be adjusted by itself to maintain good gnawing.