Product Category

Related Products

10t/h Travelling Grate Stoker

The chain chain grate can be used for supporting boilers with evaporation capacity of 1-30t/h, and is suitable for burning bituminous coal, lignite and peat. It can also be used as biomass fuel combustion equipment with bagasse, wood, rice husk and other raw materials.

Key Word:

Classification:

Chain Belt Type Grate

Email:

▌Product introduction

Chain belt type grate of the chain grate is the chain itself. The chain is driven by the chain wheel to make the grate move slowly. Grate plates are usually made of cast iron. After assembly, the necessary ventilation gap between the plates is maintained, and a separate ventilation chamber with adjustable air volume is often set under the grate, so that air can enter the fuel layer through the gap for combustion. The coal falls evenly on the grate from the coal hopper at the front of the grate. The thickness of the coal seam is adjusted by the rise and fall of a coal gate. As the grate moves backward, the coal starts to ignite, burn and burn out. The burnt ash shall be discharged manually or mechanically. There are also those who use coal spreader to throw coal at the back of the grate and move the grate forward without using coal hopper to feed coal. The speed of grate is adjusted by gear transmission according to different coal types and boiler loads.

▌Applicable scope and requirements

(一)Scope of application

Chain-belt chain grate is a mechanized layer-burning equipment, which can be used for supporting boilers with evaporation capacity of 1-25t/h, and also for various heating and drying equipment. Suitable for burning bituminous coal, lignite and peat. Specially designed, it can also be used as biomass fuel combustion equipment with bagasse, wood, rice husk and other raw materials.

(二)Use requirements

The quality of coal used in this grate shall meet the following requirements:

(1) The maximum particle size of coal shall not exceed 40mm, and it is not suitable to burn coal chips below 0-5mm.

(2) The moisture content of coal shall be less than 20%, preferably 8-10%.

(3) The ash content of coal shall not be more than 30%, but shall not be less than 10%, and the volatile content shall not be less than 20%.

(4) The ash melting temperature of coal shall be greater than 1290C

(5) The coking is not strong.

(6) The low calorific value of coal should not be greater than 4226kcal/kg

(7) If the above coal quality requirements conflict with the coal feeding setting, the highest value shall be taken.

The primary air temperature used by this grate shall not exceed 200C.

▌Structural features

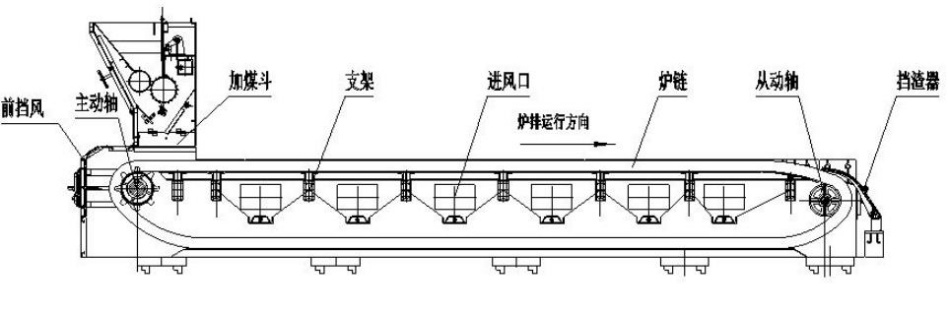

Components: 1. Driving shaft; 2. Driven shaft; 3. Support; 4. Ash discharge device; 5. Air conditioning device; 6. Furnace chain; 7. Coal hopper; 8. Front damper; 9. Side seal.

▌Model parameters

| Boiler evaporation | Effective area of grate m2 | Effective width of grate mm | Outlet shaft length (to the grate centerline) mm | Diameter of output shaft end mm | Number of air chambers |

| 1 t/h | 2.68 | 980 | 767 | Φ60 | 4 |

| 2 t/h | 3.84 | 1030 | 783 | Φ60 | 4 |

| 4 t/h | 5.39 | 1400 | 980 | Φ60 | 5 |

| 6 t/h | 7 | 1400 | 1015 | Φ80 | 5 |

| 8 t/h | 9.9 | 1960 | 1235 | Φ80 | 6 |

| 10 t/h | 11.65 | 2330 | 1662 | Φ100 | 5 |

| 15 t/h | 18.99 | 2890 | 1880 | Φ100 | 6 |

| 20 t/h | 22.6 | 3440 | 2205 | Φ120 | 6 |

▌Structure and characteristics

(1) Simple structure, low metal consumption and large ventilation section ratio; The strength and performance requirements of the main and driven shafts and grate plates are high.

(2) Several independent air chambers that are mutually decomposed are set inside the grate longitudinally. The primary air entering the air chamber decreases its speed due to diffusion and can evenly fill the air chamber. The inlet air volume of each air chamber can be adjusted by the air conditioning device

(3) Each air chamber is equipped with ash discharge device. The bottom of the air chamber is arranged with the ash dropping bottom plate with the ash dropping mouth, and the movable door connected on the ash dropping pull rod usually covers the ash dropping mouth. When the ash handle is pulled regularly, the ash will fall from the ash falling mouth to the furnace chain below, and then the furnace chain will carry it to the ash receiving hopper in the front section or near the ash removal door, and the ash will be removed manually.

(4) The grate runs normally after commissioning in the factory, and the whole machine leaves the factory. (It can also be delivered in parts according to user requirements)

▌Advantage

1. Compared with other chain grate, it has low metal consumption, simple structure, and convenient manufacturing, installation and operation;

2. Chain grate is widely used in industrial boilers for its reliable operation, stable combustion and wide fuel adaptability.