Product Category

Related Products

10t/h Reciprocating Grate

Reciprocating type grate can be matched with 1-160t/h boiler, and the range of fuel selection is wider and applicable to garbage, biomass, etc. The whole combustion surface of the grate is composed of movable grate and fixed grate, which are stacked into a stepped shape at intervals. Driven by the reducer (or hydraulic device), the movable grate can make reciprocating motion on the fixed grate.

Key Word:

Classification:

Reciprocating Type Grate

Email:

▌Product introduction

Reciprocating type grate is generally divided into inclined reciprocating grate and horizontal reciprocating grate according to its structure. The reciprocating grate is stepped and consists of fixed grate plates and movable grate plates arranged in the same way. The movable grate moves back and forth to make the coal move downward evenly. The stroke is generally 70-110 mm. If the coal quality is poor, select a large stroke.

The coal seam is squeezed, rolled, agitated when the movable grate moves, and some new coal is pushed onto the burning hot coal seam below. When the movable grate returns, some of the burning hot coal particles will be brought back to the bottom of the unburned new coal seam, so that the fuel layer has the characteristics of double-sided fire. Unlike the chain grate, there is relative movement between the coal seam and the grate, which can loosen the coal seam to increase its permeability, and the coal particles squeeze each other Friction also makes a layer of ash shell wrapped outside the hot coal particles fall off, which is conducive to the burning of coke. The reciprocating motion of the grate can also break the coke block with weak cohesiveness, which has a certain effect on fire.

▌Applicable scope and requirements

(一)Scope of application

Reciprocating type grate can be used for 1-200/h boilers, with a wider range of fuel selection.

(二)Use requirements

The quality of coal used in this grate shall meet the following requirements

(1) Particle size requirements: the maximum particle size of coal block shall not exceed 40 mm, the fine coal of 0-6 mm shall not account for less than 50% of the fuel problem, and the content of coal of 0-3 mm shall be less than 25%

(2) The moisture content of coal shall be less than 15%, and 5-10% is the best.

(3) The ash content of combustion shall not be less than 10%, and the ash melting point is better than 1200 ℃.

▌Structural features

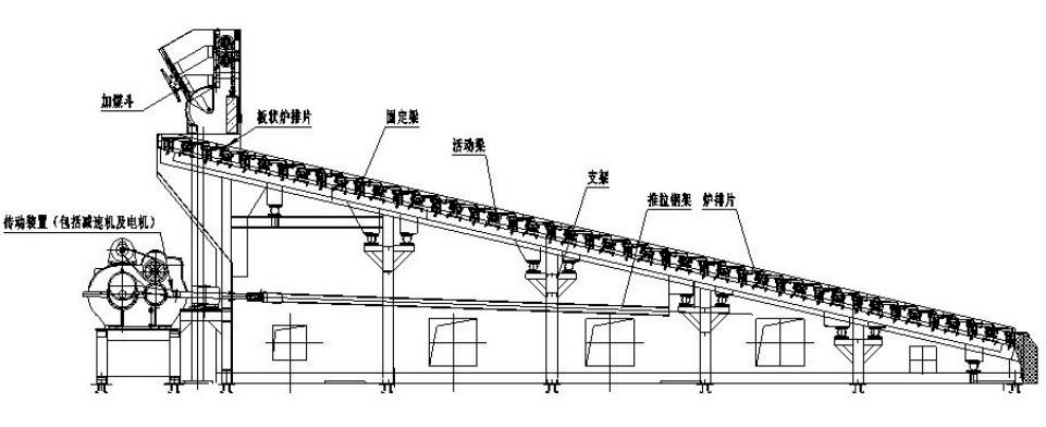

Reciprocating type grate is composed of coal hopper, support, movable beam, fixed beam, grate plate (movable grate plate and fixed grate plate) front windshield and transmission system.

▌Model parameters

| Boiler evaporation | Effective area of grate m2 | Effective width of grate mm | Ventilation sectional area ratio | Drive shaft torque N.m | Dip angle |

| 4 t/h | 5.56 | 1600 | 6-8% | 2000 | User-defined |

| 6 t/h | 6.08 | 1600 | 6-8% | 3000 | User-defined |

| 8 t/h | 8.5 | 2100 | 6-8% | 4000 | User-defined |

| 10 t/h | 12.99 | 2020 | 6-8% | 5000 | User-defined |

| 15 t/h | 22.04 | 3300 | 6-8% | 7500 | User-defined |

| 30 t/h | 29.65 | 3730 | 6-8% | 30000 | User-defined |

| 40 t/h | 40 | 4630 | 6-8% | 40000 | User-defined |

| 65 t/h | 60.16 | 7020 | 6-8% | 60000 | User-defined |

| 100 t/h | 99.56 | 10480 | 6-8% | 75000 | User-defined |

| 130 t/h | 100 | 11580 | 6-8% | 100000 | User-defined |

| 160 t/h | 153 | 14700 | 6-8% | 125000 | User-defined |

| 200 t/h | 185 | 17780 | 6-8% | 150000 | User-defined |

| 260 t/h | 248 | 18400 | 6-8% | 185000 | User-defined |

| 300 t/h | 295 | 20700 | 6-8% | 210000 | User-defined |

▌Structure and characteristics

(1) The whole combustion surface of the grate is composed of movable grate and fixed grate, which are stacked into a stepped shape at intervals. The fixed grate is installed on the grate fixed beam, and the fixed beam is fixed on the grate frame. The movable grate is embedded on the movable beam of the grate, the movable beam is installed on the movable frame, and the movable frame is placed on the bracket of the grate frame. The movable frame is connected with the external transmission mechanism by a connecting rod.

(2) When the motor is started, the connecting rod will pull the movable frame under the drive of the reducer, so that the movable grate plate will move back and forth on the fixed grate plate. The reciprocating stroke is determined according to the specific size of the grate plate and the specific coal quality of the boiler during the grate design. Generally 70-180 mm.

(3) Sectional air supply is adopted inside the grate. The grate is provided with several mutually independent air chambers along the longitudinal direction, and the air enters the air chamber from the bellows or air duct on both sides. The inlet air volume of each air chamber is regulated by the air conditioning device.

(4) The coal hopper is installed on the wall panels on both sides of the support, and the coal seam thickness is adjusted by the lifting of the coal gate.

(5) The grate can be delivered in two forms: complete and parts. Users can choose according to their needs.

(6) One of the main characteristics of the inclined reciprocating grate, which is different from the chain grate, is the relative movement of the grate and coal. When the movable grate moves backward and downward, part of the new coal is pushed to the top of the coal that has been burned. When the movable grate moves forward and upward, part of the coal that has been burned returns to the bottom of the unburned coal to heat the new coal. This kind of ignition condition is similar to that of the manual furnace, but better than that of the chain furnace. In the process of being pushed, coal is constantly squeezed, thus destroying coke block and ash shell. At the same time, the coal rolls slowly, making the coal seam loose and flat, which is conducive to combustion.

▌Advantage

1. Inclined reciprocating grate has simple structure, easy processing and manufacturing, convenient use and maintenance, and low metal consumption. Compared with chain grate, it can adapt to burning inferior fuels, such as Class II bituminous coal, Class I bituminous coal, lignite, lean coal and other coals;

2. Compared with chain grate, it is suitable for burning inferior coal with high moisture and ash content and low calorific value (12560kJ/kg) and coal easily coking;

3. When the air supply is reasonable and the air leakage is small, the carbon content in the ash is generally 18% - 20%, which is 5% - 10% lower than that of the ash from the hand fired furnace, which can save coal and reduce black smoke.