Product Category

Related Products

130t/h Cross-beam Type Grate

10-200t/h cross-beam type grate shall be a mechanized, compact and technologically advanced layer-burning equipment. It is widely used in various large boilers, heating, drying and other special equipment.

Key Word:

Classification:

Cross-beam Type Grate

Email:

▌Product introduction

The cross-beam type grate is a new type of crossbeam grate plate with oblique air outlet applied to the crossbeam grate plate. This kind of grate plate is different from the vertical upward air outlet direction of the existing grate plate. The air outlet direction of the ventilation hole of the oblique air outlet crossbeam grate plate has an included angle with the vertical direction. The horizontal speed at which the grate ventilation leaves the grate plate is conducive to the horizontal diffusion of ventilation in the coal seam, the mixing effect of coal and air, and the reduction of coal leakage from the grate.

▌Applicable scope and requirements

(一)Scope of application

The cross-beam type grate shall be a mechanized, compact and technologically advanced layer-burning equipment. The crossbeam grate is suitable for boilers with evaporation capacity of 20~40t/h or more. The main difference between its structure and the chain grate is that it uses many rigid beams. The grate plate is installed in the corresponding groove of the beam, and the beam is fixed on the drive chain. The drive chain is generally two (when the grate is very wide, several can be installed), driven by the sprocket installed on the front axle (driving shaft). It is widely used in various large boilers, heating, drying and other special equipment. Suitable for burning bituminous coal, lignite and peat; Specially designed incineration equipment can be used as other fuels, such as bagasse, various garbage, etc.

(二)Use requirements

The medium used for the grate shall meet the following requirements:

(1) The maximum particle size of coal shall not exceed 40mm, of which the content of 0~5mm coal chips shall not exceed 50%, and the content of 0~30mm coal chips shall be less than 25%.

(2) The moisture content of coal is less than 20%, and 8~12% is the best.

(3) The ash content of coal shall be less than 30%, but shall not be less than 10%, and the volatile content shall not be less than 20%.

(4) The ash melting temperature of coal shall be greater than 1250 ℃.

(5) The coking is not strong.

(6) The low calorific value of coal should be greater than 4350kcal/kg.

(7) If the above medium requirements conflict with the medium requirements of the coal feeding equipment, the highest requirement shall be taken.

The temperature of primary air used by this grate shall not exceed 200 ℃.

▌Structural features

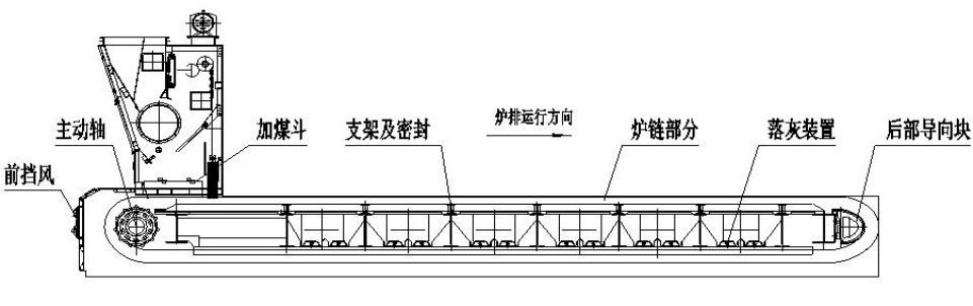

The whole grate is composed of the following parts: (1) support; (2) Furnace chain; (3) Ash discharging device; (4) Side seal; (5) Air inlet pipe; (6) Rear guide block; (7) Front windshield device; (8) Shaft assembly; (9) Coal hopper assembly

▌Model parameters

| Boiler evaporation | Effective area of grate m2 | Effective lage of grate mm | Effective width of grate mm | Drive shaft torque N.m | Air inlet mode | Ventilation sectional area ratio % | Ventilation resistance pa |

| 20 t/h | 23.29 | 6830 | 3410 | 20000 | two flanks | 8.5 | 1000 |

| 40 t/h | 35.38 | 7800 | 4550 | 30000 | two flanks | 8.5 | 1000 |

| 65 t/h | 57.6 | 8150 | 6960 | 50000 | two flanks | 8.5 | 1000 |

| 75 t/h | 63.7 | 7503 | 8490 | 70000 | two flanks | 8.5 | 1000 |

| 80 t/h | 71.2 | 8360 | 8518 | 60000 | two flanks | 8.5 | 1000 |

| 90 t/h | 80 | 9373 | 8540 | 70000 | two flanks | 8.5 | 1000 |

| 100 t/h | 97.71 | 9165 | 9570 | 90000 | two flanks | 8.5 | 1000 |

| 130 t/h | 126.66 | 9590 | 13210 | Two reducers | Isobaric air bin | 8.5 | 1000 |

| 160 t/h | 153.17 | 10458 | 14700 | Two reducers | Isobaric air bin | 8.5 | 1000 |

| 200 t/h | 185.94 | 10458 | 17780 | Two reducers | Isobaric air bin | 8.5 | 1000 |

| 260 t/h | 248.4 | 13500 | 18400 | Two reducers | Isobaric air bin | 8.5 | 1000 |

| 300 t/h | 295.2 | 14260 | 20700 | Two reducers | Isobaric air bin | 8.5 | 1000 |

▌Structure and characteristics

(1) The bracket is composed of left and right wall panels and front, middle and rear cross beams. Several relatively closed large-capacity air chambers are formed between beams, ash discharge device and air chamber partition; In this way, the air volume of each area on the grate surface can be adjusted to achieve full combustion of fuel.

(2) The chain is composed of chain link through roller, intermediate guide block, chain shaft, retaining ring, pin shaft, etc. The chain link is cast with bolt slot holes, and the beam is fixed by bolts.

(3) The grate is driven by a driving shaft at one end without a driven shaft, and the other end is equipped with a guide device; The transition of the chain between the upper guide rail and the lower guide rail is completed by the driving shaft and the guide device. The driving shaft torque is provided by the grate reducer through the coupling.

(4) The side seal is the horizontal right-angle flow channel side seal, the grate plate side seal, and the two sealing lines increase the operation safety and reliability.

(5) The ash discharging device is push-pull type; Push and pull the handle of the ash discharge door, open the ash discharge door, and discharge the fine ash and coal collected in the air chamber.

(6) Stratified coal feeding device has been widely used in coal hopper device; The coal entering the furnace is loose and stratified, and fully burnt; The thermal efficiency of the boiler is improved.

(7) The grate has compact structure and reasonable layout; The grate chain moves in the sealed guide rail, does not bear high temperature, but only bears the grate movement tension; The grate made of heat-resistant material is in contact with the coal burning at high temperature on the beam, so it will not be stressed when heated, thus extending the service life of the grate.

(8) The grate has no rear axle and eagle iron, which reduces the failure rate of the rear of the grate during operation and improves the operation efficiency.

(9) The grate chain operates in a tight state without arching and climbing; The chain movement is rolling friction, which requires low running torque and low noise.

(10) The overall sealing of the grate is good; Prevent air leakage and blow-by between air chambers. The air volume of each air chamber can be adjusted separately, which is convenient and practical.

(11) The grate surface shall be flat, the grate plates shall overlap each other and be arranged closely, so as to prevent coal leakage and falling; It is easy to replace the grate without stopping the furnace.

▌Advantage

1. The structure is rigid, the grate plate is not heated, and the beam and chain are not heated, which is more safe and durable;

2. The effective area of the grate is large, the resistance is small, and the air volume is evenly distributed;

3. The chain movement is rolling friction, requiring low running torque and low friction noise;

4. The overall sealing of the grate is good, which can prevent air leakage and blow-by between the air chambers. The air volume of each air chamber can be adjusted separately, which is convenient and practical;

5. The grate surface is flat, the grate blocks overlap each other, are arranged closely, and are not prone to coal leakage and falling, and the grate pieces are easy to replace without shutdown;

6. The ventilation cross-sectional area of the grate is large, generally up to 10% - 17%, and the combustion is extremely sufficient;

7. The grate has no rear axle and eagle iron, which makes the rear of the grate difficult to fail in the furnace.