Product Category

Related Products

50t/h-150th Complete waste incineration system

The incineration system consists of feeder, grate, ash hopper, ash conveyor and slag remover, and it is suitable for the domestic waste incineration projects with a daily capacity of 30~600 tons.

Key Word:

Classification:

Waste incinerator

Email:

Product Introduction

Process description of the waste incineration system

The incineration system consists of feeder, grate, ash hopper, ash conveyor and slag remover, and it is suitable for the domestic waste incineration projects with a daily capacity of 30~600 tons.

Process Flow Diagram

main equipment

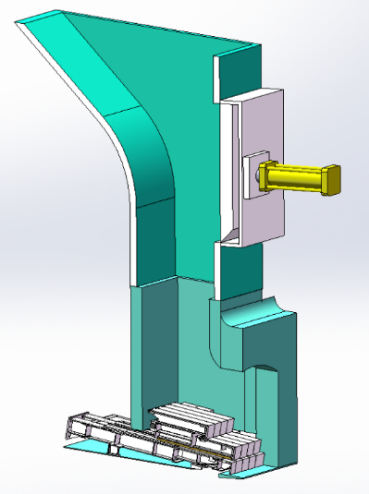

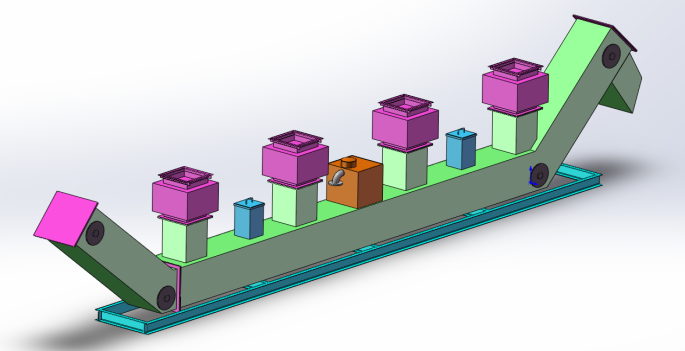

- Hopper & feeder

Feeding system consists of hopper and feeder, hopper internal gate, the gate to ensure the sealing at the same time to take into account the function of breaking the bridge, in the garbage clusters bridge blocked hopper through the gate movement to realize the bridge. The feeder and the gate are driven by cylinders to push a certain amount of garbage into the incinerator through periodic reciprocating push and pull movements, and the feeder can adjust the feeding speed according to the load of the incinerator.

|

|

|

Fuel Feeder

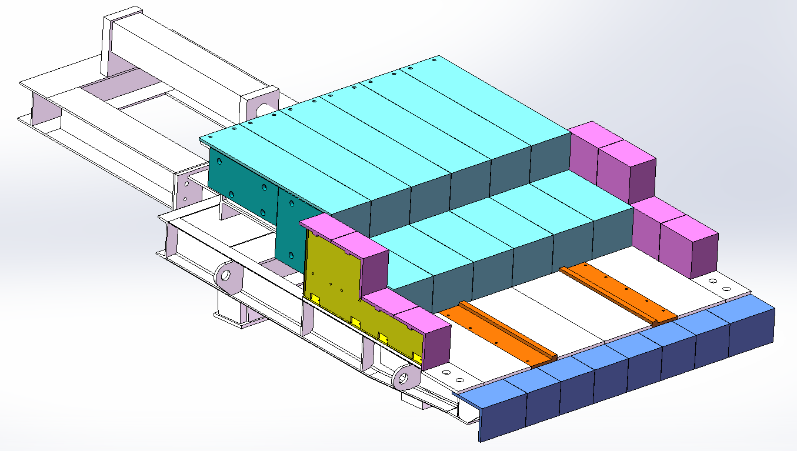

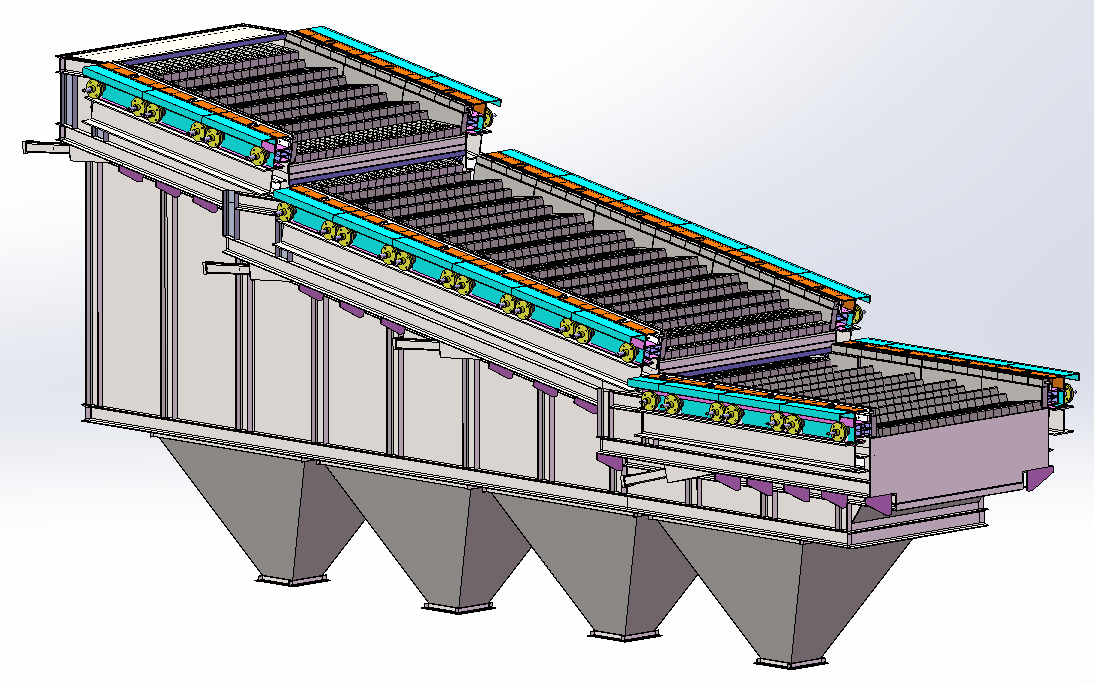

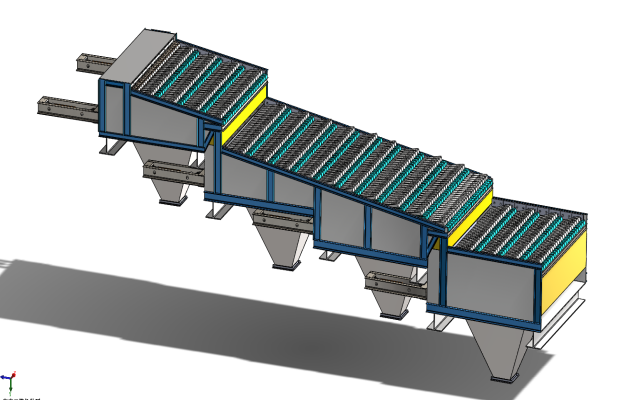

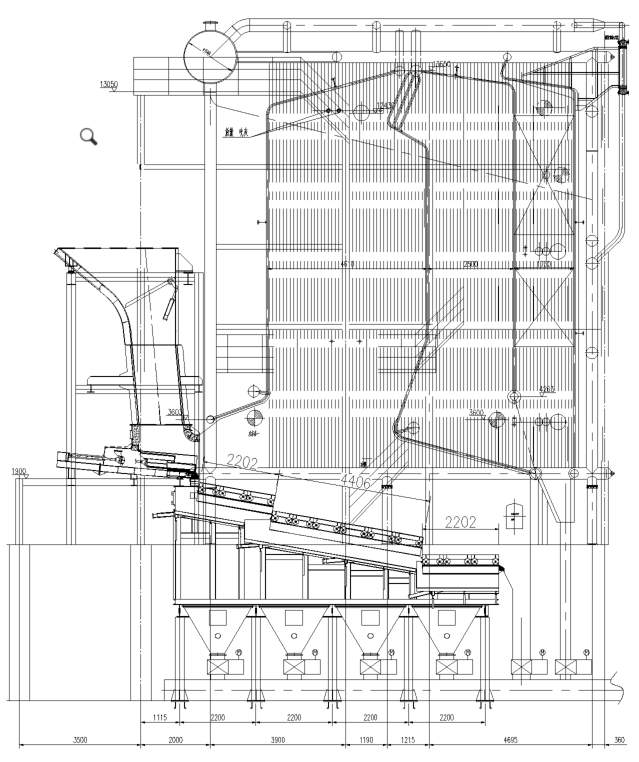

- Step Grate

MSW /garbage incineration grate is a downward-pushing stepped inclined reciprocating grate, the grate is divided into three stages of drying, combustion and burning out, and a height difference is set between each section of the grate, so that the garbage is scattered after falling and the garbage is pushed to move, and at the same time the garbage is prevented from gathering together to lead to incomplete combustion. The step grate is driven by hydraulic cylinders, and the three sections of the grate can be controlled independently, so that the movement cycle of the grate can be adjusted according to the combustion state in the furnace. The grate is made of heat-resistant cast steel, which has good wear-resistant, high temperature-resistant and corrosion-resistant properties.

|

|

|

|

Reciprocating Step Grate

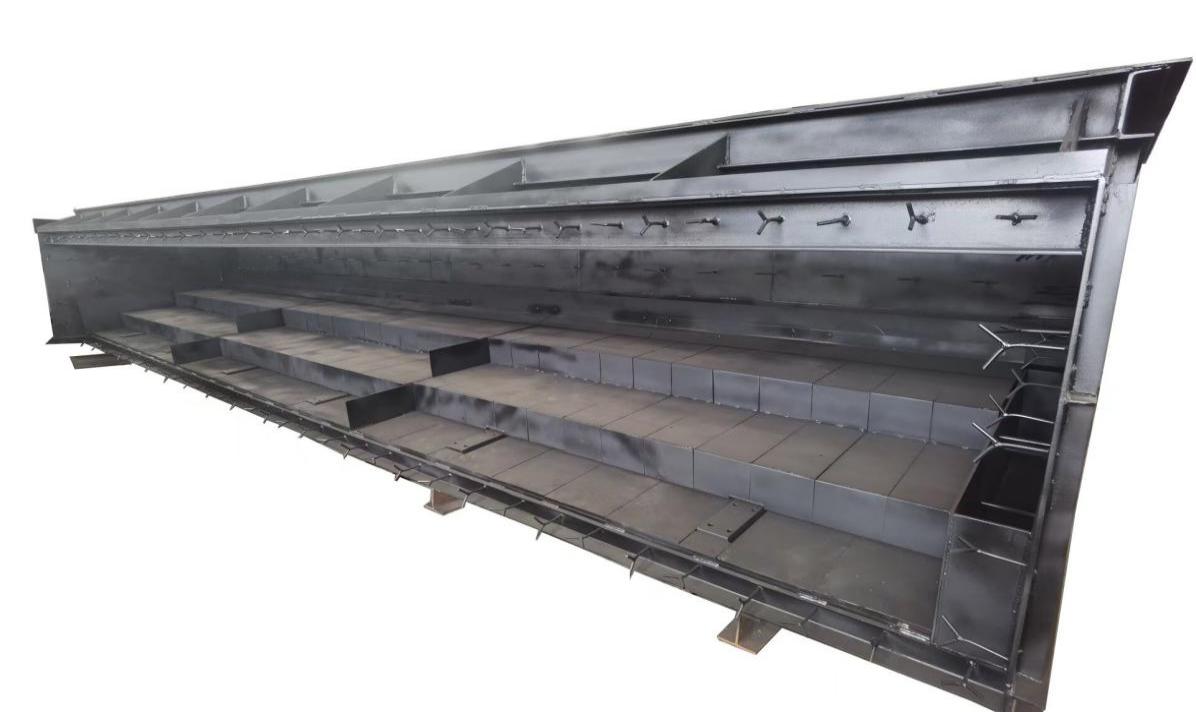

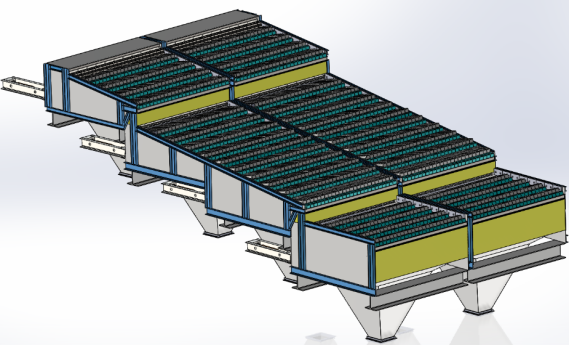

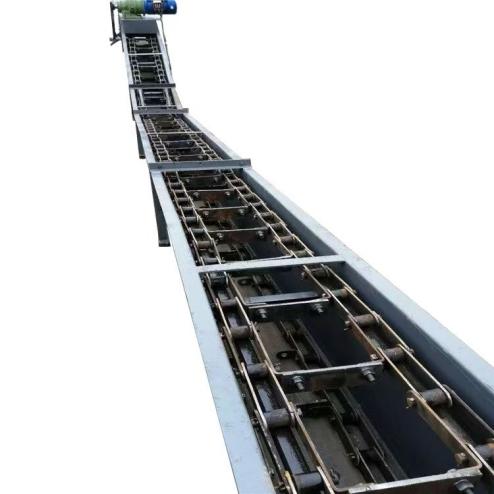

- Ash conveyor, slag remover

The ash system consists of an under-furnace ash hopper (cum air chamber), a horizontal ash conveyor, and a slag remover. The small amount of fine ash produced after complete waste combustion falls into the ash hopper through the grate gap and then collects in the horizontal ash conveyor. The main ash produced by waste combustion is pushed into the slag bucket through the grate of the combustion section, and then enters the wet slag remover together with the fine ash. All the ash is sent to

the slag pit by the slag remover.

|

|

|

|

Ash conveyor, slag remover

Process Characteristics

- Simple structure, easy to operate and maintain;

- The grate is resistant to high temperature, corrosion and abrasion, with low replacement rate;

- Even air distribution of the grate, uniform combustion of garbage;

- Adequate garbage incineration, thermal scorch reduction rate ≤5%;

- Equipment modularization, easy installation, short construction period;

- The equipment is fully automated.

scope of services

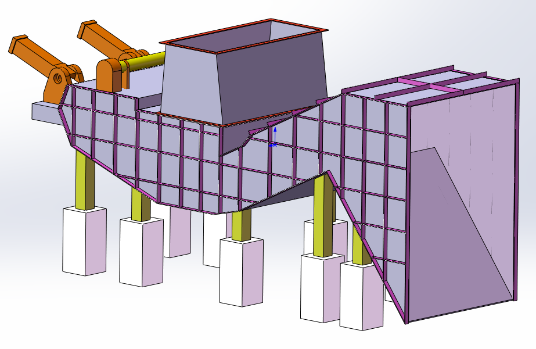

- Reliable waste incineration equipment

|

|

|

|

|

Incineration equipment

- Complete waste incineration process solution

Application solution

|

CAPACITY |

Technological Process |

Basic Parameter |

Scope of Application |

|

50t/d |

①Garbage into the furnace → incineration → cooling → flue gas treatment → standard discharge ② Garbage into the furnace → incineration → waste heat boiler → flue gas treatment → standard discharge |

Daily processing capacity: 50t Saturated steam capacity: 3~5t/h |

The project with a daily processing capacity of 50t is suitable for harmless and reduced treatment of domestic waste in small areas of villages and towns. Depending on the project situation, the high-temperature flue gas can be directly cooled and purified before being discharged, or a 3~5t/h saturated steam boiler can be used to produce and sell steam. It is not suitable for power generation. The project is small in scale. Under the premise of meeting the same environmental protection standards, the input per ton of garbage is too high, and the project has no profit point and is not economically feasible. It is suitable for non-profit demonstration projects or reliable steam users to increase a certain output value. The incinerator and the waste heat boiler in this scheme are arranged horizontally separately and connected by high-temperature flues. Compared with traditional large-scale waste incineration projects, the overall height of the equipment in this scheme is significantly reduced, and the total equipment height is below 20m. |

|

100~200t/d |

Waste into the furnace → incineration → waste heat boiler → flue gas treatment → standard discharge |

Daily processing capacity: 100~200t Saturated steam capacity: 8~20t/h |

The project with a daily processing capacity of 100t is suitable for harmless, resource-based and reduced treatment of domestic waste in small areas of villages and towns, and waste heat recovery and utilization. It is equipped with 8~10t/h saturated steam boilers. The scale is too small and unstable, and it is not suitable for power generation. However, the steam output is considerable, and it needs to be sold for profit or used in combination with other industries that need steam. The incinerator and waste heat boiler are arranged separately and horizontally. |

|

200~300t/d |

Waste into the furnace → incineration → waste heat boiler → flue gas treatment → standard discharge, steam used for power generation |

Daily processing capacity: 200~300t Superheated steam capacity: 16~30t/h Annual power generation: 32~48 million kwh |

The project with a daily processing capacity of 200~300t is suitable for harmless treatment of domestic waste in counties and waste heat recovery, and is equipped with a 20~30t/h superheated steam boiler + 4~6MW steam generator set. |

project case

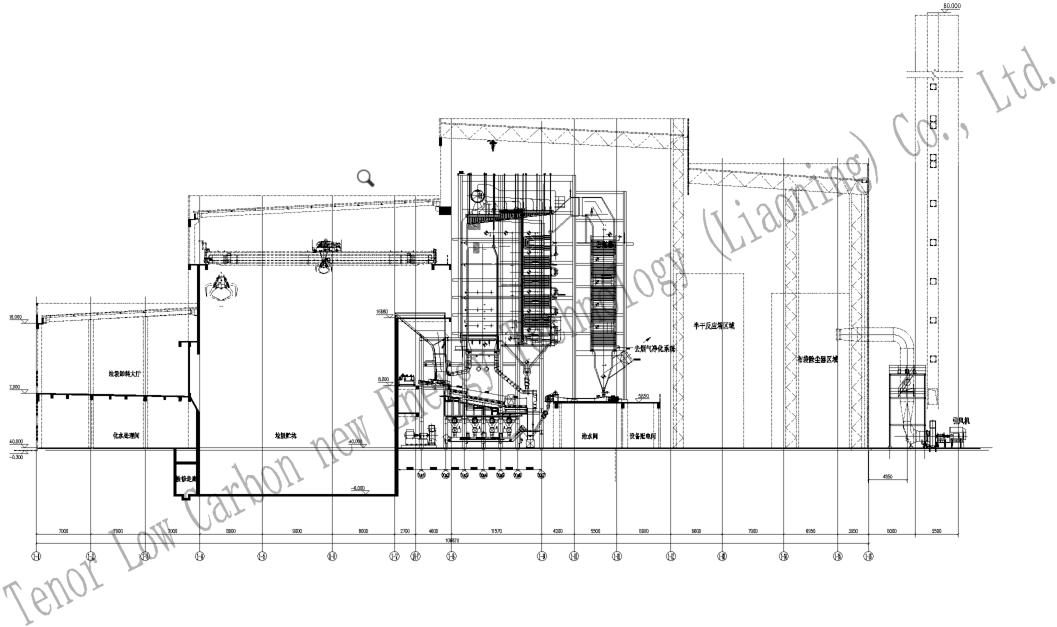

- Ho Chi Minh City, Vietnam, 600t/d Waste Incineration Power Generation Project (large waste incineration power generation project)

The 600t/d waste incineration power generation project in Ho Chi Minh City, Vietnam uses our three-step inclined reciprocating grate furnace for daily treatment of 600t waste, with 75t/h steam boiler +18MW generator set. The project is currently under construction and is scheduled to be put into operation in December, 2024.

Project plan drawing

|

|

|

|

Shipment pictures