APBE recommend Brand | Dalian Sunshine Boiler Brightness in August 2024 Asia Pacific International Biomass Energy Exhibition

Aug 01,2024

cordially invited

The invitation

Dear customers and friends:

Hello, everyone! Our company will participate.2024Year8Month8-10Day in Guangzhou·The exhibition hall of the Canton Fair“2024Section12Asia-Pacific International Biomass Energy Exhibition(APBE)”, Will bring you biomass chain grate, reciprocating grate, garbage incinerator grate, pusher, slag remover and other supporting equipment.

At that time, we sincerely invite customers and friends to visit the booth and exchange more products and services. Welcome to the exhibition site for detailed discussion!

Enterprise Introduction

Dalian Sunshine Boiler Auxiliary Co., Ltd.

Dalian Sunshine Boiler Auxiliary Co., Ltd. was established in1998Year, with fixed assets5The headquarters is located in Yaojia Industrial Zone, Ganjingzi District, Dalian City, and the production base is located in Yantun, Paoya Township, Wafangdian City, covering an area30More than 10,000 square meters, employees300People, main production equipment550Yu Tai, machining, riveting, casting, assembly, etc.5Large production workshop. Advanced technology, complete processing equipment, complete detection means, long-term domestic3500A number of boiler enterprises,6000A number of enterprises to produce supporting equipment, is one of the largest boiler auxiliary production enterprises, products are exported to Japan, South Korea, Turkey, Mexico, Colombia, Thailand, Vietnam, the Philippines and so on50Multiple countries.

The main products are: coal, biomass chain grate, reciprocating grate, garbage incinerator, various structures of slag removal machine, coal machine, coal mixer, customized casting products and other boiler accessories products and other supporting equipment.

New recommend

waste incineration system

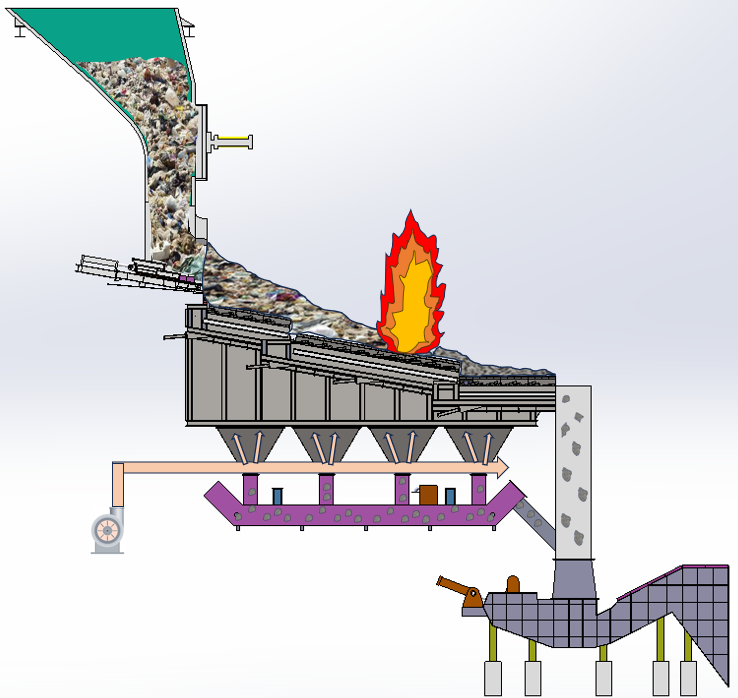

The incineration system consists of feeder, grate, ash hopper, ash conveyor and slag remover, which is suitable for daily processing capacity.30~600Tons of domestic waste incineration projects.

- Process Flow Diagram -

The garbage is sent to the hopper by the garbage crane or conveyor, It is stacked above the feeder and is periodically pushed into the furnace by the feeder. After the garbage enters the furnace, it passes through the three-stage grate of drying, burning and burnout. The primary air with a certain pressure and temperature is sent into the downwind chamber of the grate, and passes through the garbage material layer from bottom to top through the air hole on the grate surface and the grate gap, providing heat for garbage drying and oxygen for garbage full combustion. The ash produced by the complete combustion of garbage enters the wet slag remover through the slag hopper and is discharged into the slag pit. A horizontal ash leakage conveyor is connected below the air chamber, and a small amount of ash leaked from the grate is sent to the wet slag remover.

-Delivery of hydraulic pusher-

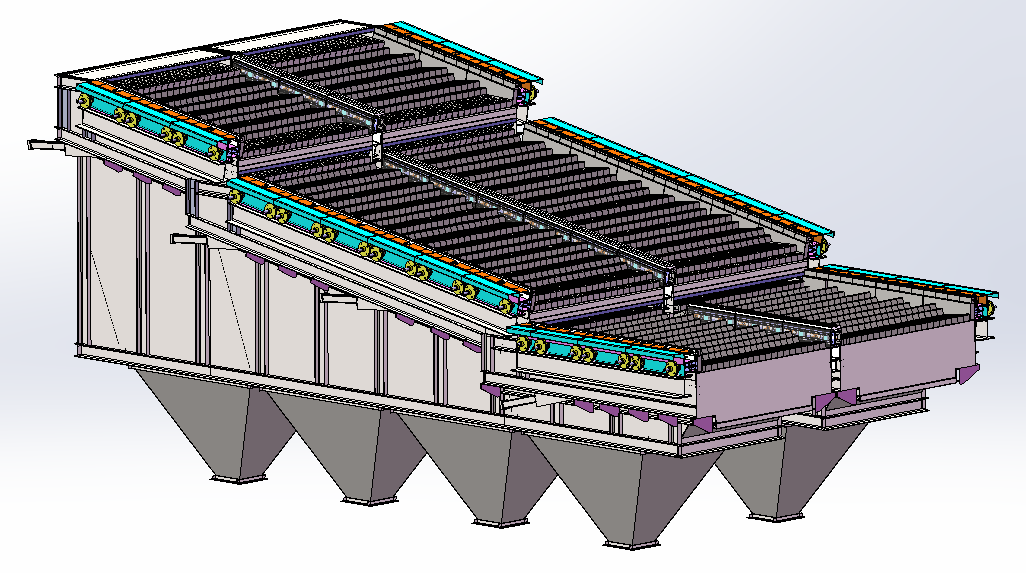

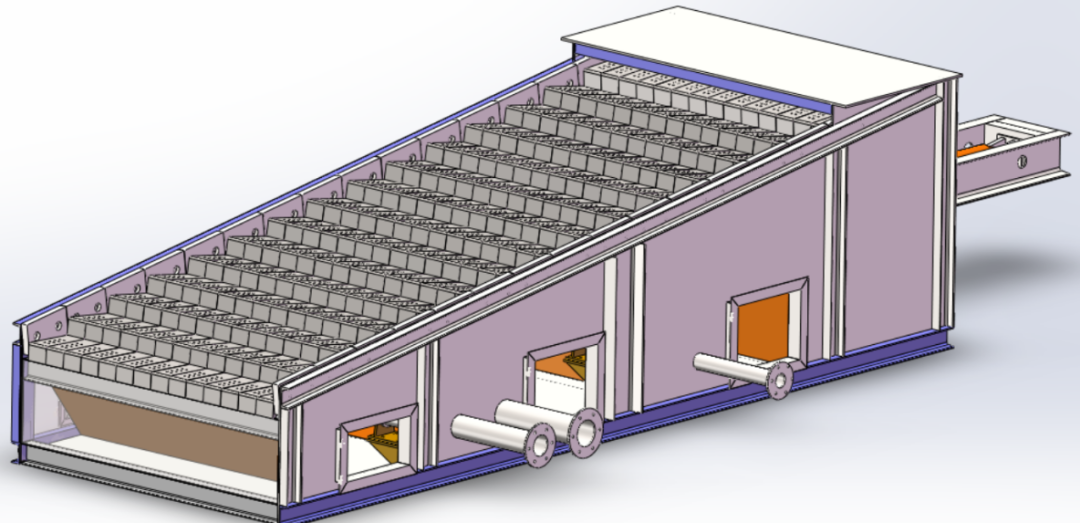

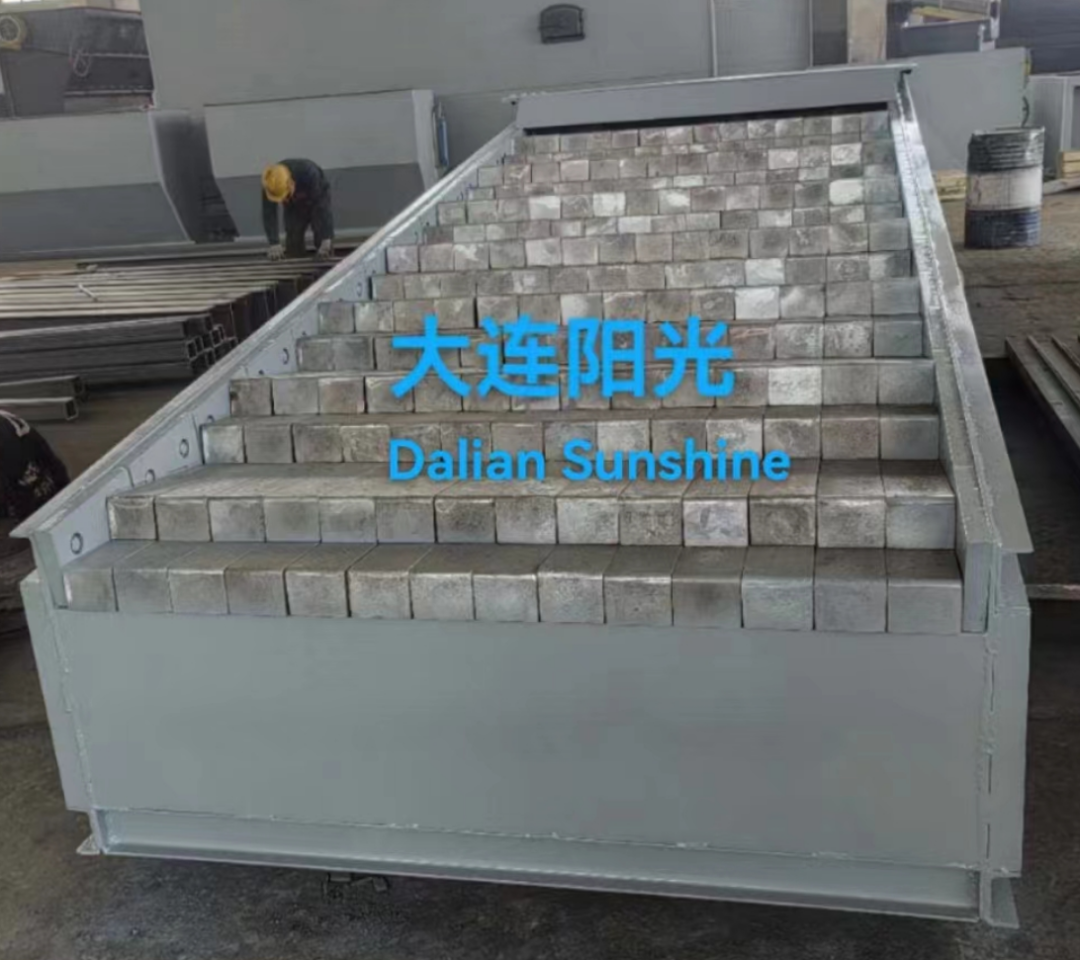

Step-by-step reciprocating grate

The waste incineration grate is a step-by-step inclined reciprocating grate. The grate is divided into three stages: drying, burning and burnout. A height drop is set between each grate, and the waste is scattered after falling, which promotes the movement of the waste while avoiding incomplete combustion caused by garbage agglomeration. The grate is driven by an oil cylinder, and the three-stage grate can be controlled independently, and the grate movement cycle can be adjusted separately according to the combustion state in the furnace. The grate is made of heat-resistant cast steel, which has good wear resistance, high temperature resistance and corrosion resistance.

Process characteristics:

1) Simple structure and easy operation;

2) Grate high temperature resistance, corrosion resistance, wear resistance, low replacement rate;

3) The air distribution of the grate shall be uniform, and the garbage combustion shall be uniform;

4) Full waste incineration, heat burning reduction rate≤5%;

5) Modular equipment and short construction period;

6) All equipment is automated.

25mlong beam grate

Large Transom Chain Grate

sectional reciprocating grate

Scale grate

reciprocating grate

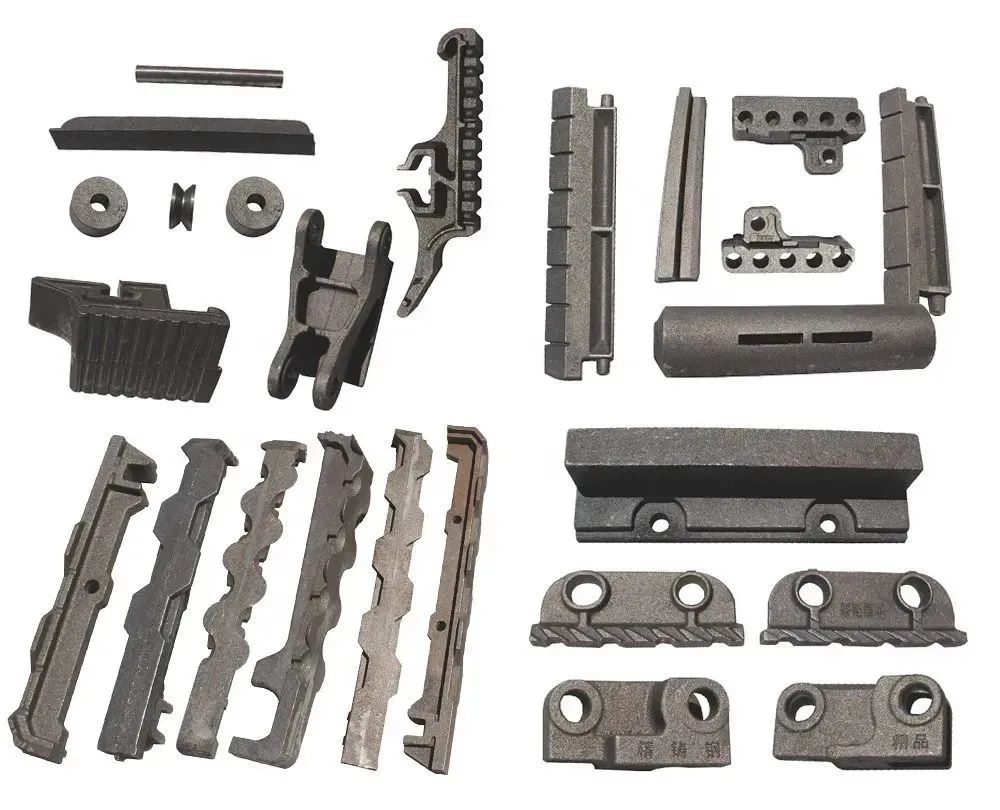

Grate Accessories

Slag remover

Coal feeder

Project Case

Mexico beam grate installation site

Vietnam20ton segmented reciprocating grate site

Philippines30ton scale grate site

Colombia45ton beam grate site

Ho Chi Minh City, Vietnam600tWaste Incineration Project

Ho Chi Minh City, Vietnam600t/dThe waste incineration power generation project adopts our company's three-step inclined reciprocating grate furnace for daily treatment.600tGarbage, collocation75t/hsteam boiler 18MWGenerator set, currently under construction of the project,24Year12Monthly plan to start production.

*The above pictures and information are from Dalian Sunshine Boiler Auxiliary Co., Ltd.

Not allowed to modify the use without permission, offenders will be prosecuted